GRP SMC Panel Tanks

GRP SMC panel tanks are a new type of tank made of high quality SMC panels. These panels are

made from (SMC) Sheet Moulding Compound which comprises Glass Fibre, Polyester Resins,

Catalysts and Fillers. The compound is fed into heavy hydraulic presses and is pressed with

a constant temperature of 150°C.

GRP SMC Panel Type Water Storage Tanks are versatile due to their modularity, low

maintenance, and excellent thermal and hygienic properties. GRP SMC Panel Type Water Tanks

storage system has been designed and developed for the singular purpose of meeting these

demands efficiently, with flexibility, with uncompromising levels of quality and

reliability. Specified to meet the most rigorous conditions, it has become the first choice

around the world for applications ranging from individual homes to major building and

industrial complexes.

GRP SMC Panel Type Water Tanks system is supremely flexible. Small units, from 1m3 (260USG),

serve as an integral element at the point of use in a piped delivery system. Larger units,

even up to 10,000m3 (2,500,000USG), provide free-standing long term storage

capacity.

The growth of algae and other microorganisms is closely related to light. To prevent this

requires light transmission of less than 0.1% in direct sunlight. All standard GRP SMC Panel

Type Water Tanks molded panels have a light transmission of less than 0.005% to prevent

algae growth even if the tank is installed in full sunlight. Growth of algae, if allowed to

occur, will adversely affect water taste, and can lead to disease such as gastro-enteritis

General Specifications

Standard: Singapore Standard SS245: 1995 Cross

reference to British Standard BS 7491 Part 3:1994 and BS EN 13280:2001

Materials: Resin-Isophthalic unsaturated polyester

resin conforming to BS 3532 specification Fiber Glass-Low alkali fibre glass conforming to

JIS R3411 to R3417 or BS 3396, BS 3496 and BS 3749 specifications.

Testing Method: BS 2782

Manufacturing Process: SMC hot pressed compression

moulding

Tank Structural Support:

External: Standard Type: Hot Dipped Galvanised Steel

– Optional Type:

External Braced type (Metal-Free tank internal for non-partitioned tank only)

Internal: Standard Type: SS 304 Tie-Rod or

Cleat/Angle Stay SS316 – Optional Type: Tie-Rod or Cleat / Angle Stay

Roof Support: PVC Vertical Poles and GRP roof panel

stiffener

Sealant: Nontoxic PVC foam

Bolt, Nuts, Washers:

External: Standard Type: Hot Dipped Galvanised Steel

Optional Type: SS 304/A2 or SS 316/A4

Internal: Standard Type: SS 304/A2 (In-contact with

water) – Optional Type: SS 316/A4 (In-contact with water)

Roof: Hot Dipped Galvanised Steel or unless otherwise

specified

Ladder:

External – Standard: Hot Dipped Galvanised Steel

Internal – Standard Type: PVC Optional Type: GRP or

316

Water Level Indicator:

Standard Type: Reversed Reading Mechanical Ball Float

Type with Mouse

Optional Type: Direct Reading Clear Tube Type

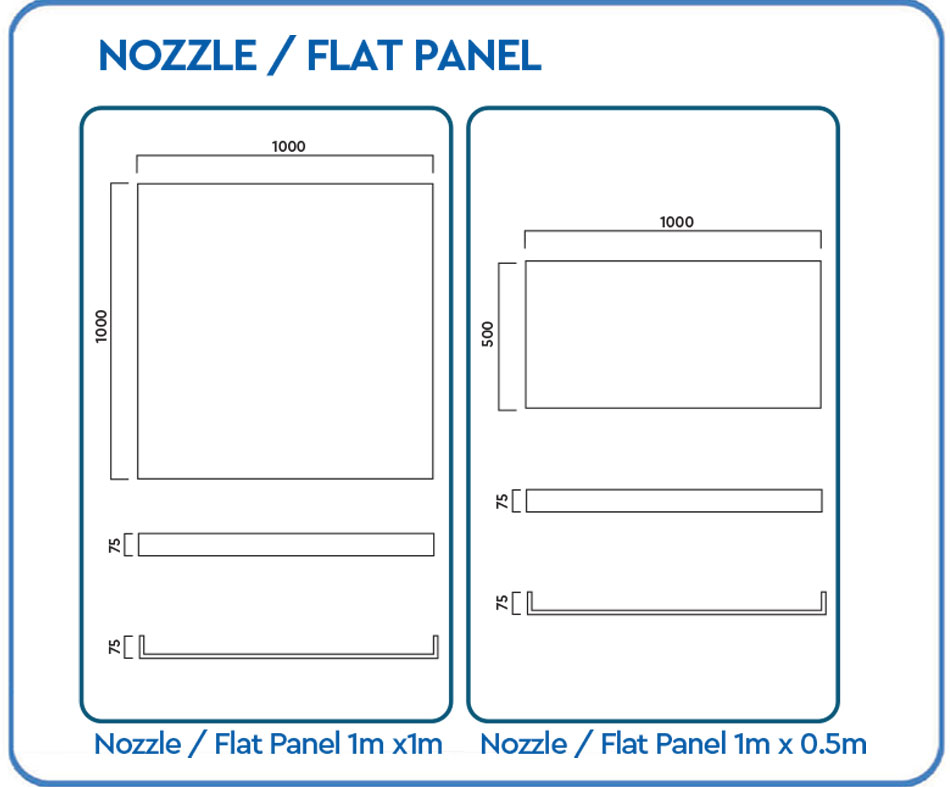

Nozzle Panel: Flat panels will be provided for any

type of piping materials.

Why You Should Select APEX GRP Sectional Water Tank?

■ Exceptionally clean water storage, with WRAS approval.■ Smooth surface finish on both sides of panel to prevent algae and bacterial growth on panels.

■ Exceptional corrosion resistance with the corrosion proof nature of GRP panel.

■ Each panel and components are manufactured with stringent quality control.

■ Excellent strength and rigidity, designed with a safety factor of 6.

■ Strong resistance to high UV and harsh weathering conditions.

■ Ease of handling, transportation, installation and maintenance.

■ Panel design is modular and could accommodate various size and shape requirements to fit space constrained site conditions.

■ Excellent thermal insulation performance with the option of an insulated panel

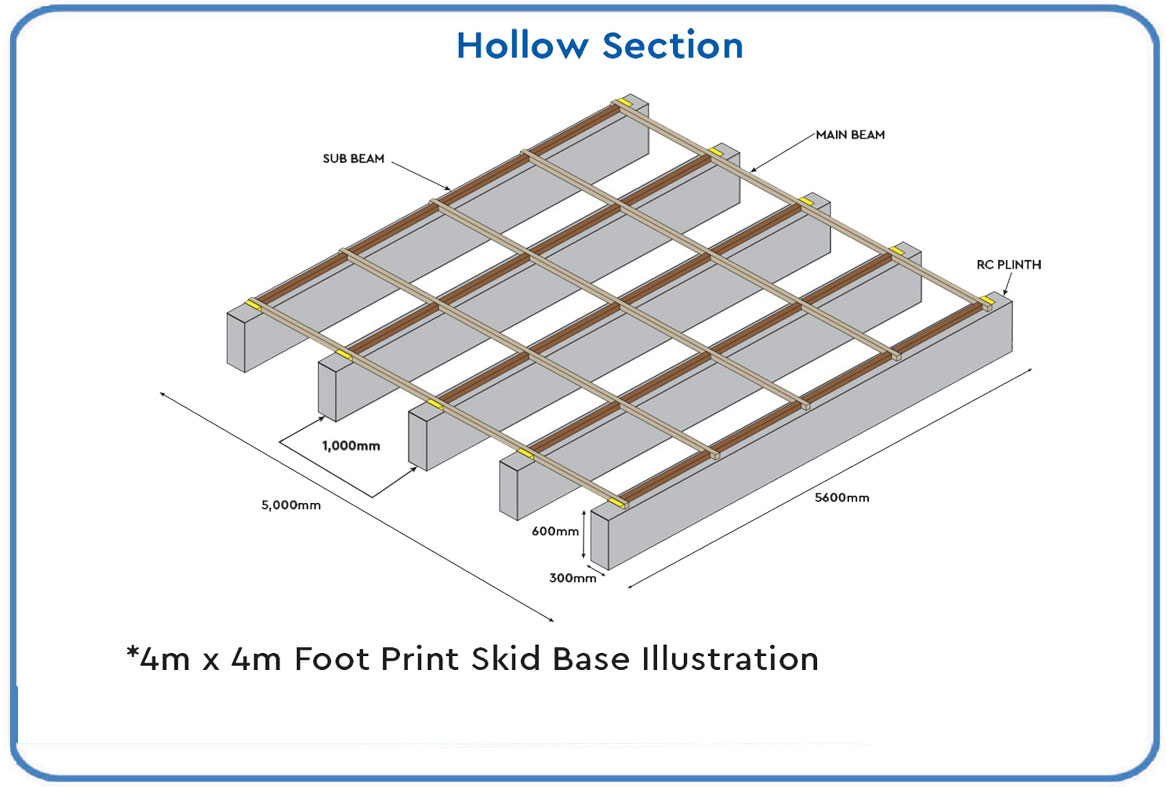

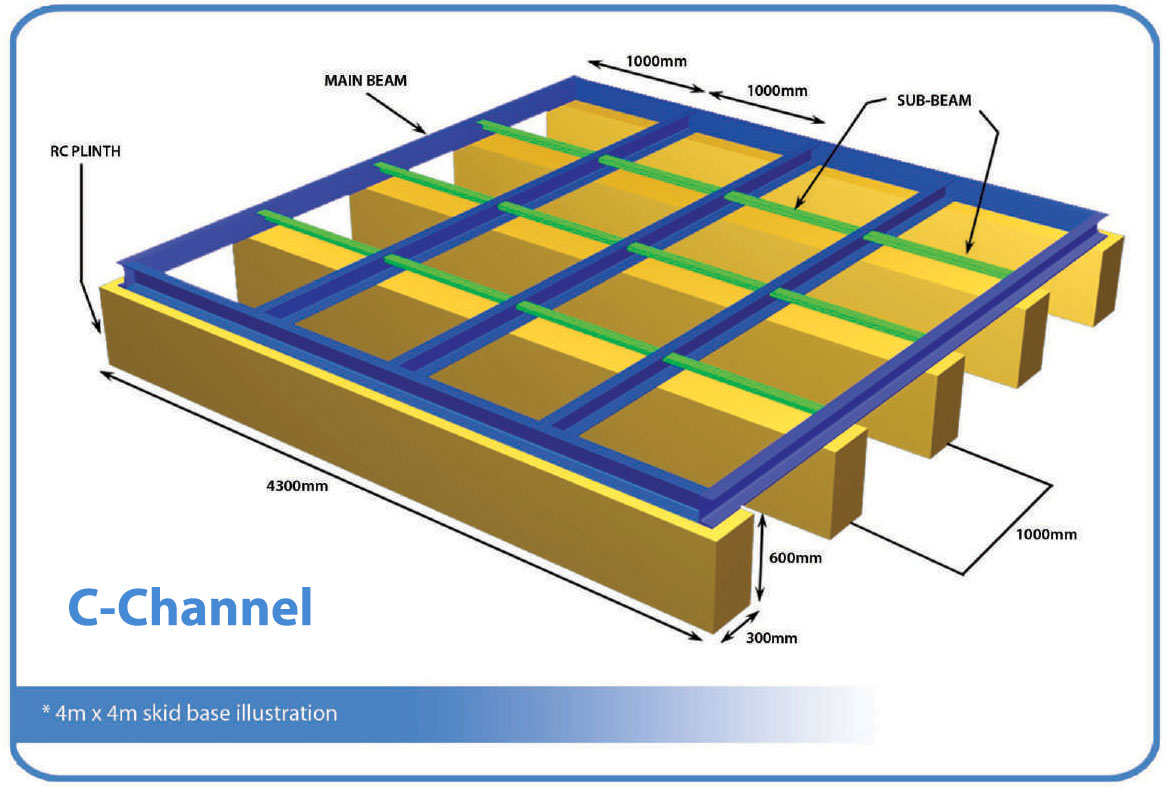

Skid Base Specifications for GRP sectional water tank

*4m x 4m Foot Print Skid Base Illustration| Tank Height | Main Beam | Sub Beam | Concrete Plinth Distance |

|---|---|---|---|

| 1.0 m | not provided | not provided | 1000mm c/c |

| 1.5 m | Hollow Section 50mm x 50mm x 3mm | Hollow Section 50mm x 50mm x 3mm | 1000mm c/c |

| 2.0 m | Hollow Section 50mm x 50mm x 3mm | Hollow Section 50mm x 50mm x 3mm | 1000mm c/c |

| 2.5 m | Hollow Section 50mm x 50mm x 3mm | Hollow Section 50mm x 50mm x 3mm | 1000mm c/c |

| 3.0 m | Hollow Section 50mm x 50mm x 3mm | Hollow Section 50mm x 50mm x 3mm | 1000mm c/c |

| 3.5 m | C-Channel 150mm x 75mm | Angle 75mm x 75mm | 1000mm c/c |

| 4.0 m | C-Channel 150mm x 75mm | Angle 75mm x 75mm | 1000mm c/c |

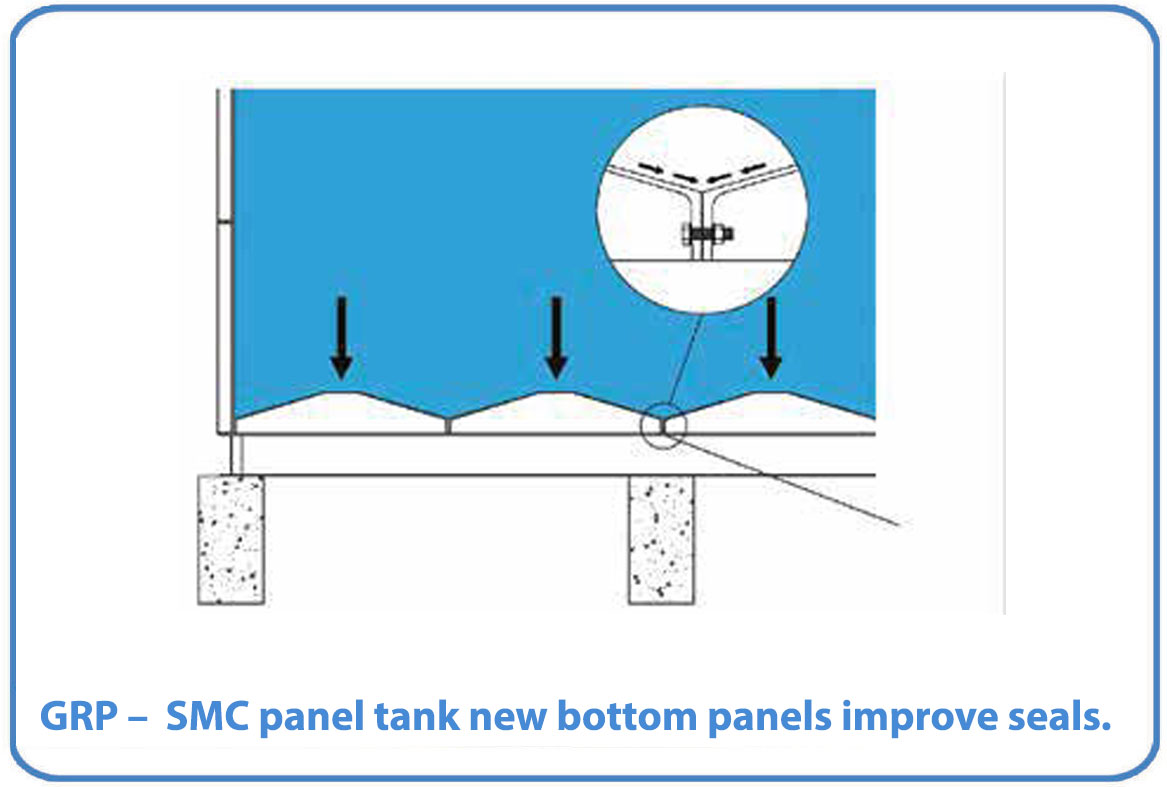

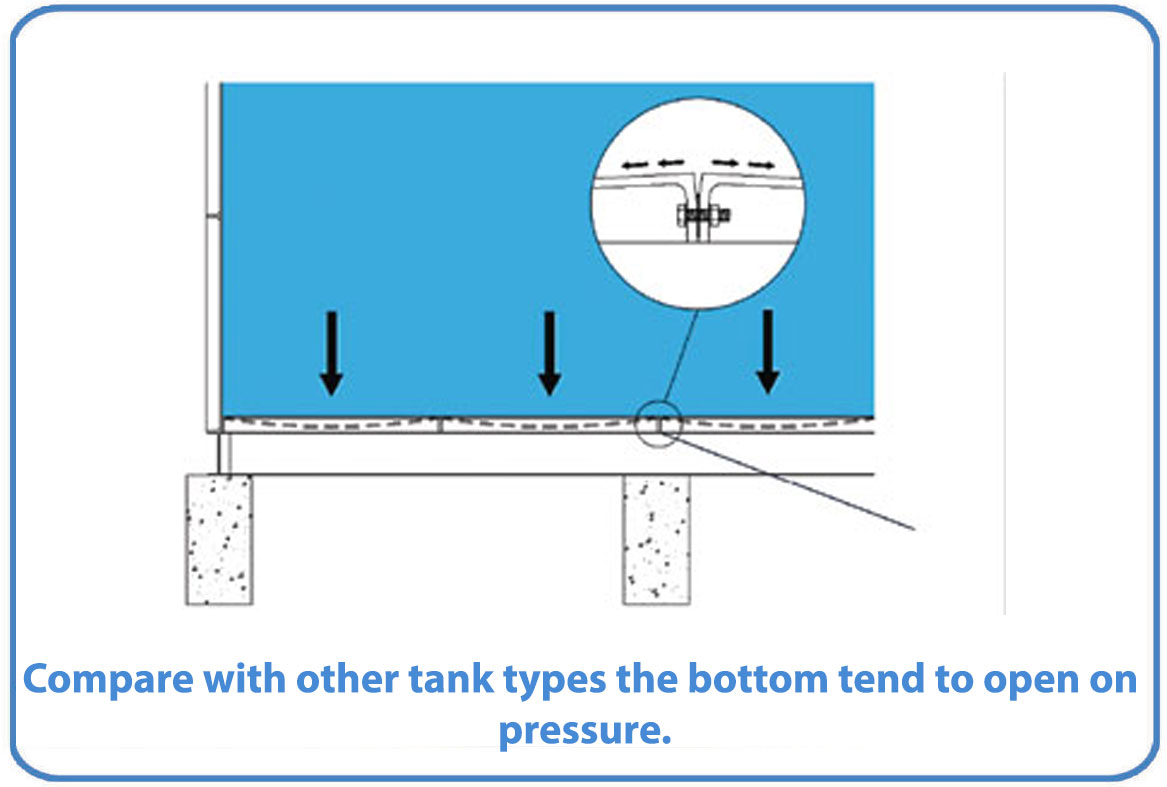

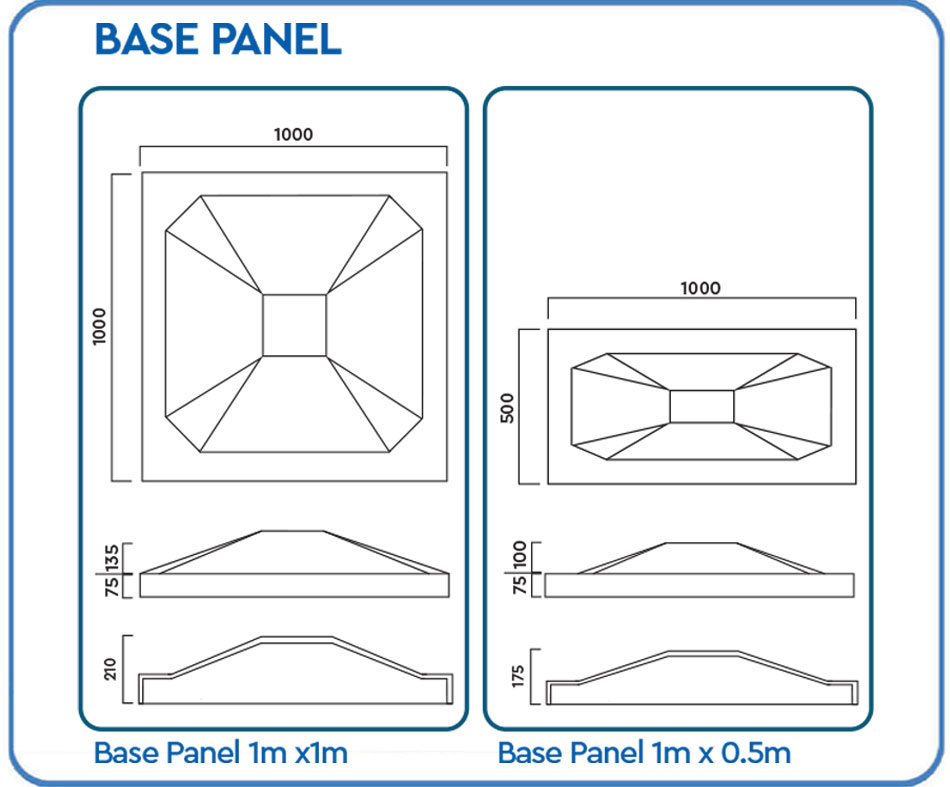

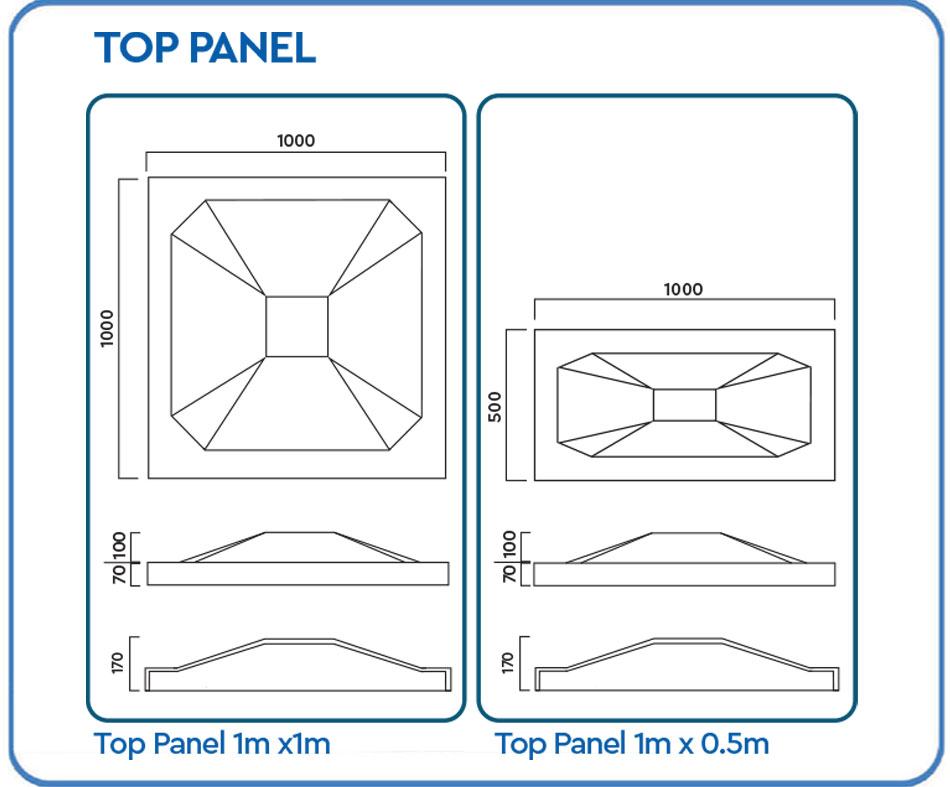

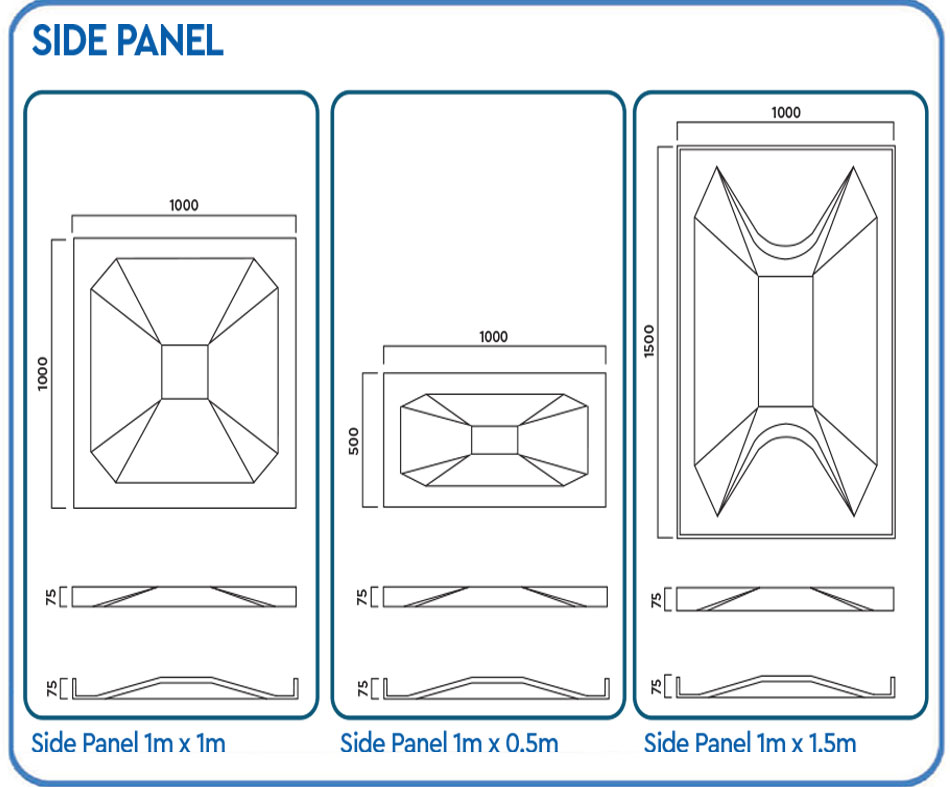

Panel Design

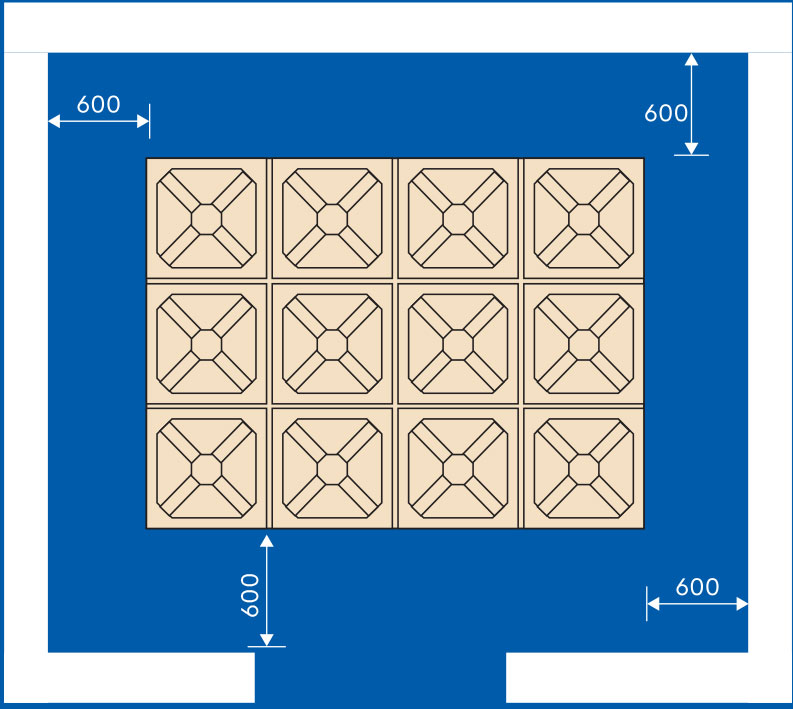

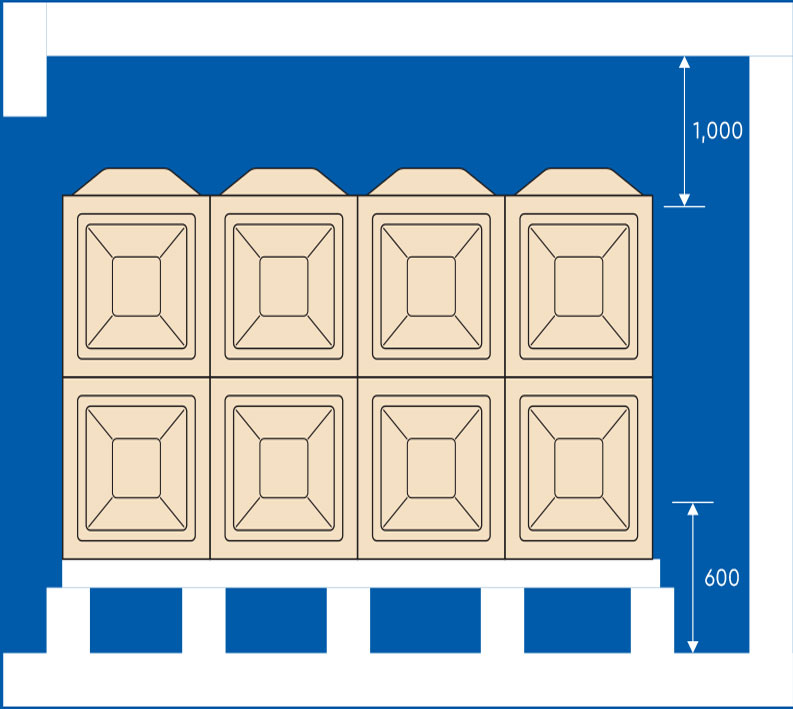

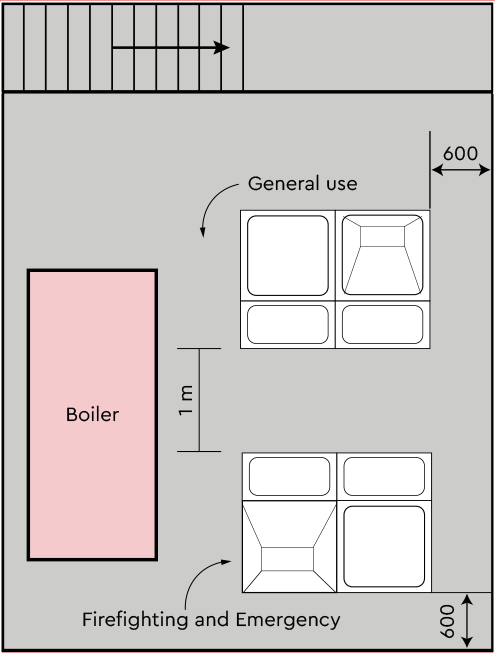

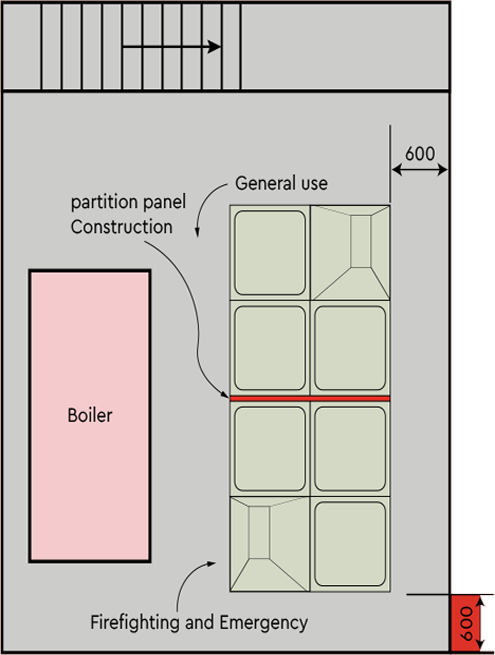

Installation Space

About 600mm space in all directions is required as shown at the bottom image for maintenance and installation of tanks