GRP Pre Insulated SMC Panel Tank

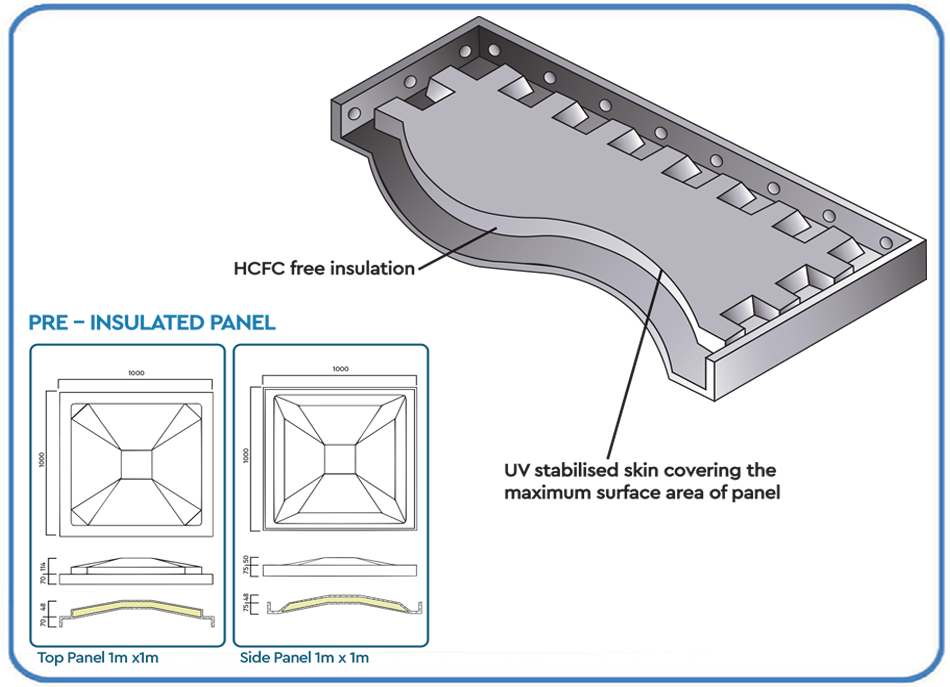

GRP – Pre Insulated SMC panel tank Type (1) tank insulated panel has rigid polyurethane (PU)

foam, of low thermal conductivity, sandwiched between inner FRP layer and outer Resin cover,

as shown. These composite panels are used on the sides and base of the tank, which are

directly in contact with the water. Additional protection is not required for the roof of

the tank, since a static air layer between the water surface and the tank provides good

insulation.

The Pre Insulated SMC material, from which all the GRP SMC panel type water tanks are

manufactured, is light, corrosion – free and highly durable, very strong in both tension and

compression, and rigid. Unlike steel, it has a low coefficient of expansion, minimizing

stress at all fixings caused by temperature variations. Design criteria for all tanks,

summarized in table, established a massive 8 times safety factor of panel strength over

maximum anticipated load – proof against the worst natural disasters of the last 100

years.

Features

■ The convex base panels transmit water pressure to the panel joints, increasing the sealing pressure as water level increases.■ The joints themselves are further sealed with a flexible rubber sealant, developed from advanced technology in rubber products, which maintains its properties in all temperatures.

■ GRP – Pre Insulated SMC panel tanks have similar capabilities to its’ non insulated type yet has a significant thermal resistance with strength and durability against natural disasters.

■ The Pre Insulated SMC insulated panels have been specially developed with rigid polyurethane foam with low thermal conductivity values. The foam is moulded in between the GRP panels as shown below.

General Specification

GRP Insulated Sectional Water Tanks Internal Tie-Rod Tank & External Braced Tank Owing to the extreme climatic conditions APEX Offers GRP INSULATED SECTIONAL WATER TANKS.By encapsulating a 25mm – 50mm layer of rigid polyurethane foam, APEX pre-insulated panel could maintain the desired water temperature stored inside the tank under extreme temperature conditions. APEX pre-insulated panels could be selected for water storage where there is a need to stabilize the temperature against extreme heat or freezing conditions so as to prevent dew formation.

Green Conscious

The world is showing an increased awareness of environmental issues when selecting materials for construction or otherwise. The concept of “Green Buildings” is slowly becoming the norm rather than the exception. Recyclability, sustainability and carbon footprint impacts are becoming important considerations when designing infrastructure and building. The life cycle of a water tank from anufacture through to its disposal is becoming the approach to choosing the most suitable tank for a building or outdoors.Our externally reinforced FRP Panel Type Water Tanks offer significant environmental benefits – they weigh less and require less energy to transport & install than equivalent steel tanks, they have excellent mechanical properties and are corrosion free. Design life is in excess of 40 years and over this time, maintenance requirements will be minimal

Panel Design

FRP Panel Type Water Tanks have a design life in excess of 40 years. It is likely the tank will last well after this time, with minimal maintenance during its lifecycle required. Ultimately, the steel supports and the GRP panels can be completely recycled as scrap or put to other uses.| Characteristics | APEX GRP - Tank Panel Performance | Acceptance Criteria (SS 245:2014 Specification) |

|---|---|---|

| Tensile Strength (MN/m²) | 107 | >70 (min) |

| Bending Strength (MN/m²) | 167 | >100 (min) |

| Elastic Modulus in Bend (MN/m²) | 11953 | >6000 (min) |

| Glass Content (%) | 33 | >25 (min) |

| Barcol Hardness | 59 | >30 (min) |

| Water Absorption (%) | 0.2 | 0.5 (max) |